Trusted by Today’s Most Innovative Companies

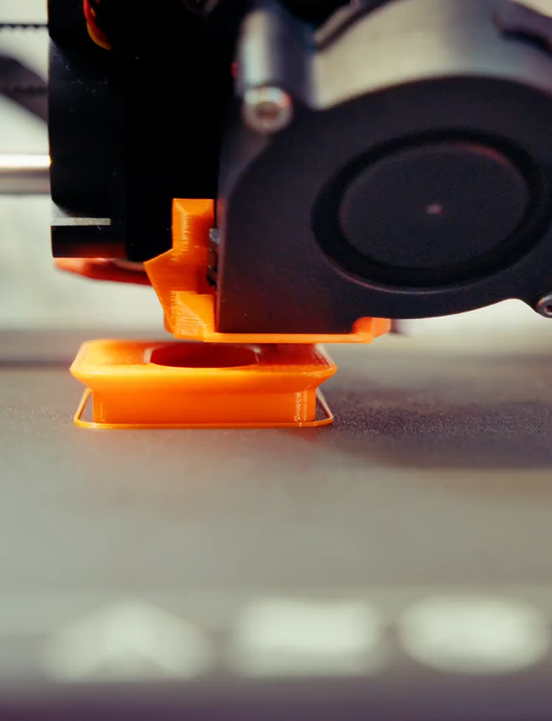

SolutionsFuture-Ready Solutions

Future-Ready Solutions

for Additive Manufacturing

Leading Metal 3D Printing Company in India

About Wipro 3D

Wipro 3D Case Studies

0

Yearsof experience in additive manufacturing

0

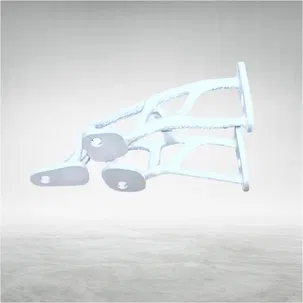

Customersserved across aerospace, space, defence, automotive, oil & gas, and energy sectors

0

Materialssupported across diverse industrial applications

0

Fasterfulfillment — from design to delivery

Our Products

Quality Certifications

Quality Certifications

- End-to-end support for product qualification, including in-house testing.

- Nadcap & API 20S: Standards for quality, reliability and precision.

- ISO 9001, ISO 27001, and EN/AS9100 compliance across industries.

- Secure handling of proprietary data with secure digital workflows.

- Traceable production logs for regulatory and engineering confidence.

NADCAP Accredited

API 20S Compliance

ISO 9001 : 2015

AS 9100

ISO 27001