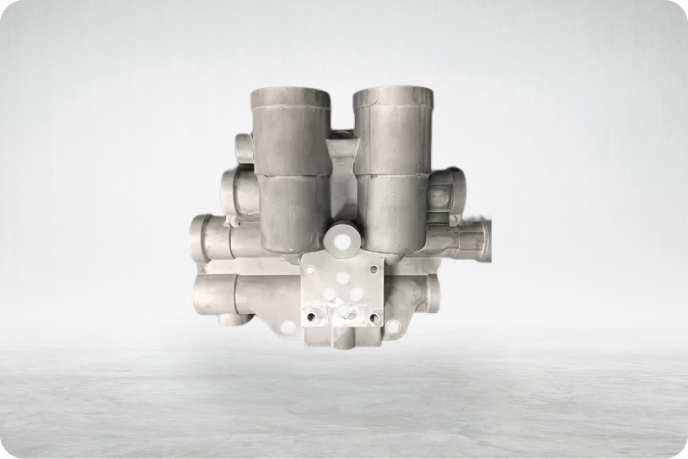

High Pressure

Compressor Stator

The Stator converts kinetic energy into static pressure

CATEGORY

Aerospace

MATERIAL

Ti6Al4V

The Aerospace industry has been at the forefront of adapting Metal Additive Manufacturing (AM) and some of the most evolved applications of metal AM can be found in the aerospace sector. Leading OEMs, tier 1 suppliers, and key ecosystem players are in the phase of developing mature capabilities in metal AM.

Typical value contribution from Metal Additive T Manufacturing comes in form of weight reduction, reduction in sub-assembled parts by creating monolithic designs, ability to realize complex designs and drastic reduction in lead time to realize components.

About the Project

AM Competencies Used

Additive Design & Engineering

Due to it’s large size, the Stator was creatively sectioned into different zones to achieve the desired geometry, dimensions and functionality.

Post Processing

A series of well-planned post processing activities were coordinated and executed to achieve the Stator’s desired features critical to performance i.e. pe particularly surface finish and weight.

AM Value Addition

Time-to-realize

The complete design to realize lifecycle for the Combustion Chamber was done in less than 5 months, a drastic time compression compared to the traditional 14 months.