Sensor

Housing

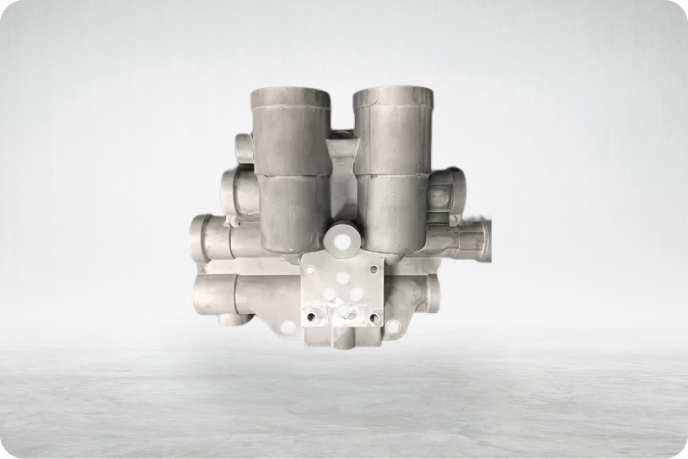

The Sensor Housing is a critical component of a fighter jet response system with intricate…

CATEGORY

Defence

MATERIAL

AlSi10Mg

The defense industry is among the earliest adopters of Additive Manufacturing along with the Aerospace industry. In a myriad of applications State-run defense agencies and private defense organizations are using AM in highly critical projects for missiles, fighter jets, customized equipment, handheld weapons, drones, respiratory gear, and much more. The defense logistics and product acquisition processes are already in the process of transformation with the help of relatively small and tactical AM centers deployed in army, naval and air force establishments. Perhaps the most impactful application of AM could be portable in-field AM centers deployed near conflict zones.

About the Project

AM Competencies Used

Post Processing

A series of well-planned operations were incorporated into the realization strategy. Special media was used to get a highly fine finish on the inner surface of the channels.

Build Technology

The Sensor Housing has a complex geometry with entwined channels and with certain features very critical to the functionality of the component. Build parameters and Orientation were Or optimized to ensure a monolithic component.

AM Value Addition

Time-to-realize

Originally, multiple welding and brazing operations were involved adding to the manufacturing duration. Wipro 3D realized the housing in 2 days

Additive Design & Engineering

The Sensor Housing was originally made as 7 discrete pieces which were integrated into a monolithic