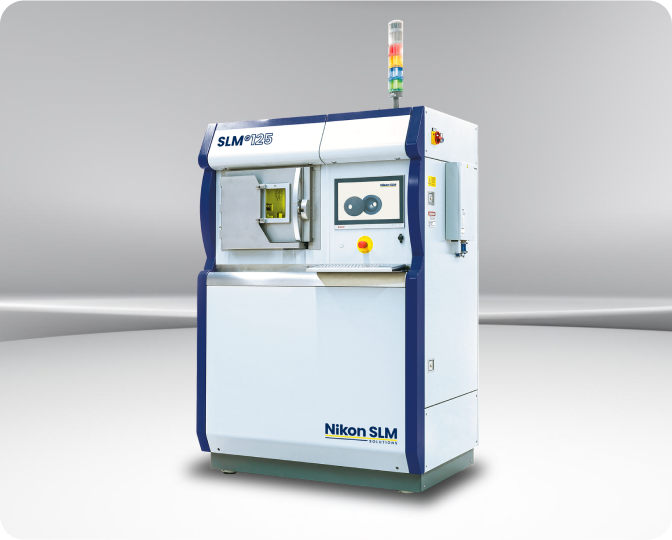

SLM®125

Industrial 3D Printer

Designed for rapid prototyping and low-volume manufacturing, this compact yet powerful system offers tailored solutions for industries demanding high-quality metal components. With its advanced features and intuitive interface, the SLM®125 streamlines production processes, empowering you to stay ahead in today's competitive market.