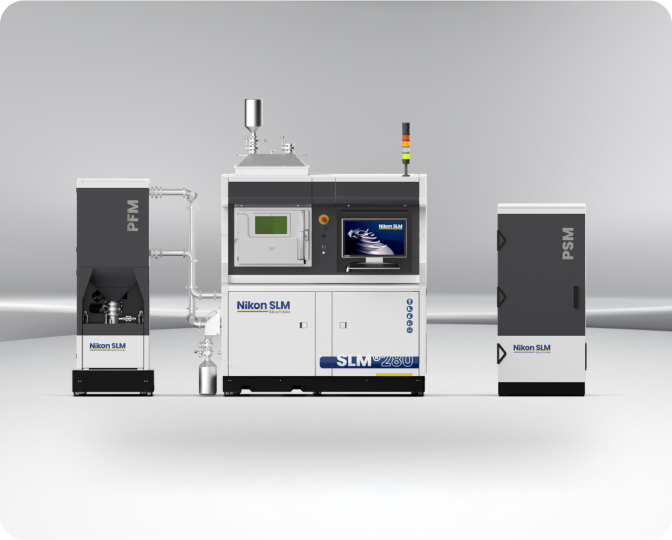

SLM®280

Industrial 3D Printer

Experience the future of metal additive manufacturing with the SLM®280 2.0. This innovative system combines precision engineering with advanced technology to deliver unmatched performance and reliability. From prototyping to serial production, the SLM®280 2.0 offers tailored solutions for industries seeking to optimize production processes and drive innovation.