Additive Manufacturing in the Oil & Gas, Energy Sector

Wipro 3D: Supporting Critical Systems Through Additive Manufacturing

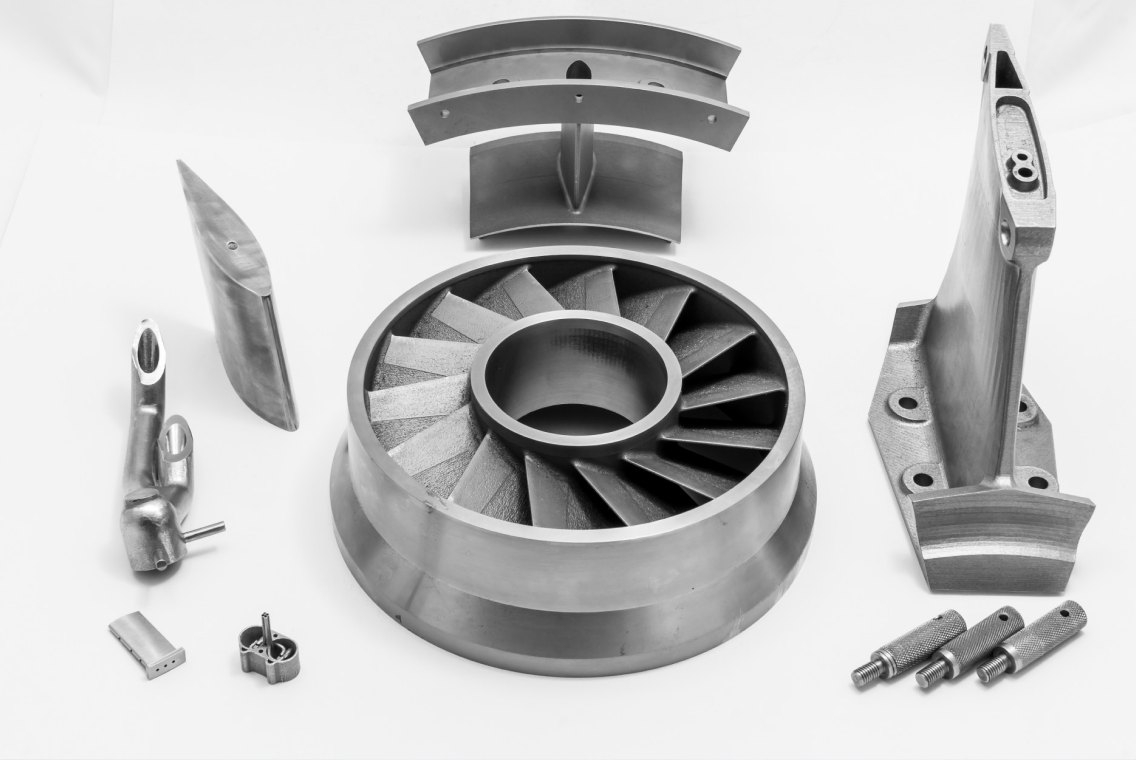

Critical Spares & Obsolete Parts

- Reverse engineering of legacy and discontinued components

- On-demand production of corrosion-resistant spare parts

- Surface finishing and qualification for field-ready deployment

Flow Control & Pressure Systems

- Enables monolithic printing of complex parts to minimize assembly requirements

- Supports rapid customization and design variations without additional tooling costs

- Enhances performance through integrated internal channels and cooling features

Energy Infrastructure Support

- Printed spare parts for turbo equipment, mounts, and cable guides

- Lightweight additive manufacturing hardware for marine and offshore applications

- Small-batch and low-volume production for critical oil and gas components

Case Studies

Quality Certifications

Quality Certifications

- End-to-end support for product qualification, including in-house testing.

- Nadcap & API 20S: Standards for quality, reliability and precision.

- ISO 9001, ISO 27001, and EN/AS9100 compliance across industries.

- Secure handling of proprietary data with secure digital workflows.

- Traceable production logs for regulatory and engineering confidence.

NADCAP Accredited

ISO 9001 : 2015

EN 9100: 2018

API 20S Compliance

ISO 27001

Why Wipro 3D?

Energy Sector Focus

Proven track across Oil & Gas, Energy and Marine

Reverse Engineering Capability

From scan to qualified part

Certified Parts

API 20S-certified components

Agility

Low-volume and just-in-time manufacturing

Reduce Lead Times and Improve Part Longevity with AM

Wipro 3D enables Oil & Gas, Energy and Marine companies to produce mission-critical components more efficiently, safely and intelligently - bridging the gap in industrial 3D printing.